Rotatek provides 3D marine alignment services and precision measurement solutions including main engine alignment, reduction gear alignment, tail shaft coupling sag and gap alignment, stern tube and strut bearing bore alignment, cardan shaft and strain gauge alignment. Utilizing the latest laser technologies available, we are able to perform these services faster with higher accuracy than traditional methods saving valuable outage time and resources.

Excessive vibration on marine vessels can often be the result of misalignment which can ultimately lead to failures and costly repairs. For the safe and reliable operation of your propulsion system, precision alignment is an essential requirement.

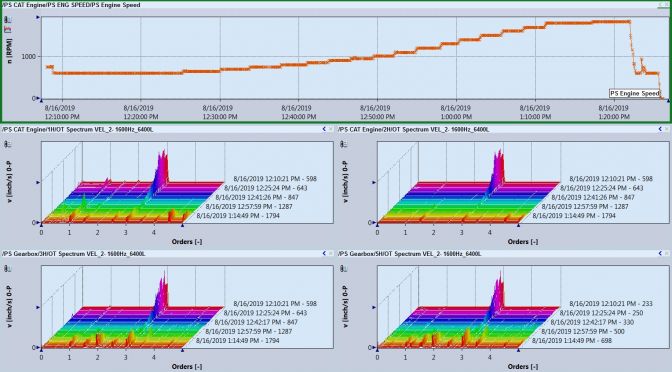

A detailed graphical measurement report is supplied with all marine alignment services.

Our commitment to excellence paired with our state-of-the-art measurement capabilities makes Rotatek your trusted precision service partner.

how Can we Help you?

Our expert team is ready to help you with your next project. Explore the industries we serve or contact us to learn more.

Why Align?

Misalignment Costs Time and Money

Did you know over 50% of rotating equipment failures are directly related to misalignment and unbalance? Misaligned or unbalanced equipment are subjected to higher vibration levels significantly reducing the service life of bearings, seals, shafts and couplings.

Precision Alignment Benefits

- Reduced Overall Operating Costs

- Reduced Power Consumption

- Reduced Machinery Vibration

- Reduced Wear on Bearings, Seals, Shafts and Couplings

- Reduced Machinery Failures