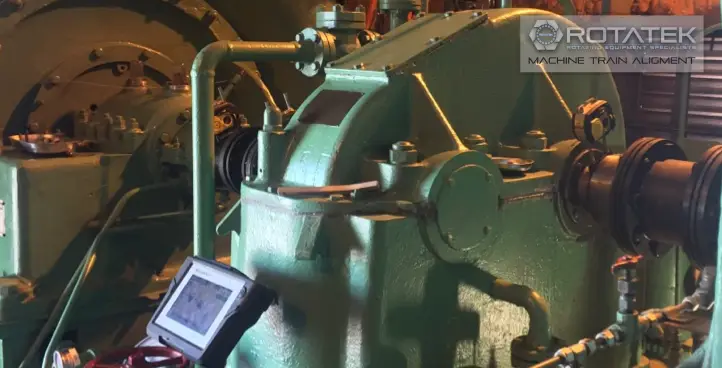

Machine Train Alignment—From Installation to Operation.

At ROTATEK, we deliver high-precision machine train alignment services that reduce downtime, improve reliability, and extend the life of your rotating equipment. Whether during installation, overhaul, or routine maintenance, our proven alignment solutions outperform traditional methods—saving valuable outage time and operational resources.

Complete System Alignment for Complex Machinery

Machine train alignment involves aligning three or more connected machines with at least two couplings. Rather than treating each machine pair in isolation, we approach the alignment as a unified system—allowing us to calculate the fewest, most effective correction moves needed to bring the entire train into tolerance.

ROTATEK uses adaptive industry-leading laser alignment technology and custom bracketing to measure multiple couplings simultaneously. Our systems simulate alignment corrections in real time—ensuring the proposed moves will achieve precision results before any adjustments are made. With live multi-coupling move monitoring, we track both horizontal and vertical movement as it happens, guaranteeing fast, accurate results with minimal guesswork.

how Can we Help you?

Our expert team is ready to help you with your next project. Explore the industries we serve or contact us to learn more.

SIMULTANEOUS MULTI-COUPLING LASER ALIGNMENT

At ROTATEK, our advanced laser alignment systems allow us to measure and align machine trains consisting of up to 14 machines and 13 couplings in non-classified areas and up to 6 machines and 5 couplings in ATEX/EX hazardous areas—all in a single setup. This multi-coupling capability streamlines the alignment process, reducing downtime, cutting costs, and ensuring every component in your drivetrain is precisely aligned for optimal performance and reliability.

Industrial machine train alignment is a complex process that requires careful planning, attention to detail and highly skilled operators in order to achieve accurate, reliable results in a timely and efficient manner.

Alignment Expertise Across Industrial Machine Trains

-

Motor – Gearbox – Compressor

-

High-Pressure Turbine – Low-Pressure Turbine – Generator

-

Engine – Gearbox – Pump

-

Boiler Feed Pump – Turbine – Gearbox – Booster Pump

What Sets Our Machine Train Alignment Service Apart

At ROTATEK, machine train alignment is more than a service—it’s a precision-driven process backed by decades of experience, certified quality, and industry-leading equipment. We specialize in aligning complex, multi-coupling systems with accuracy, speed, and confidence. Here’s how we stand apart:

✅ Simultaneous Multi-Coupling Measurement

We can align up to 14 machines (13 couplings) in a single setup, significantly reducing compounded alignment errors and saving valuable time during critical outages.

✅ Virtual Move Simulation

Before any physical adjustments are made, alignment corrections are simulated using advanced software. This ensures accuracy, avoids trial-and-error, and minimizes unnecessary rework.

✅ Live Adjustment Monitoring

With real-time live move monitoring, we track both horizontal and vertical movements during alignment—confirming in-tolerance conditions as corrections are made.

✅ System-Wide Alignment Approach

We evaluate the machine train as a whole—not just individual pairs. This helps prevent bolt-bound and base-bound conditions while accounting for thermal growth, soft foot, and other mechanical variables.

✅ Expertise in Thermal Growth & OL2R Compensation

Our alignment plans are built for real-world operation. We model thermal expansion, structural flexing, and offline-to-running (OL2R) shifts to ensure your alignment holds under load—not just at rest.

✅ Certified, Field-Tested Technicians

All services are performed by seasoned field engineers trained in mechanical diagnostics, rotating machinery, and laser metrology. We are AS9100D and ISO 9001:2015 certified, ensuring technical excellence and traceable results.

✅ Fast Turnaround, Less Downtime

Our alignment process minimizes machine disassembly, optimizes shim and move strategies, and speeds up execution—cutting costs and reducing your time offline.

✅ Detailed Digital Reporting

We deliver clear, graphical reports showing as-found and as-left alignment data, coupling offsets, angularity, and thermal targets—ideal for maintenance records and compliance.

✅ Industry-Wide Versatility

From turbines, compressors, and gearboxes to motors, pumps, and extruders, ROTATEK delivers machine train alignment across power generation, aerospace, marine, manufacturing, and heavy industry.

Industry Standards for Horizontal Shaft Alignment

At ROTATEK, horizontal shaft alignment services are performed using industry-recognized methods and alignment standards to ensure your rotating equipment operates at peak performance. Where applicable, we follow the guidelines outlined in ANSI/ASA S2.75-2017 Part 1, which defines shaft alignment tolerances, measurement procedures, and acceptable misalignment limits for horizontally mounted machinery.

This standard provides the foundation for achieving accurate coupling alignment, reducing mechanical stress, minimizing vibration, and extending the lifespan of bearings, seals, and couplings.

By aligning to ANSI/ASA standards where applicable, we deliver precise, data-driven results that improve reliability, reduce downtime, and maintain compliance with OEM and industry requirements.

At ROTATEK, precision isn’t just a promise—it’s our certified standard. As an AS9100D and ISO 9001:2015 certified company, we back our commitment to quality with globally recognized benchmarks for excellence. With decades of field-proven expertise in precision measurement, laser alignment and 3D metrology, we deliver unmatched accuracy and reliability across aerospace, defense, power generation, marine, and general industry.

Our expert technicians adapt to the most demanding environments, offering tailored solutions with fast nationwide response times, 24/7 availability, and a proven quality management system built for mission-critical performance. We utilize cutting-edge equipment and industry-leading software to ensure your critical components meet the tightest tolerances—every time.

Ready to Align with Excellence?

Contact us today to schedule your machine train alignment service or to discuss a custom solution tailored to your operational and equipment needs.