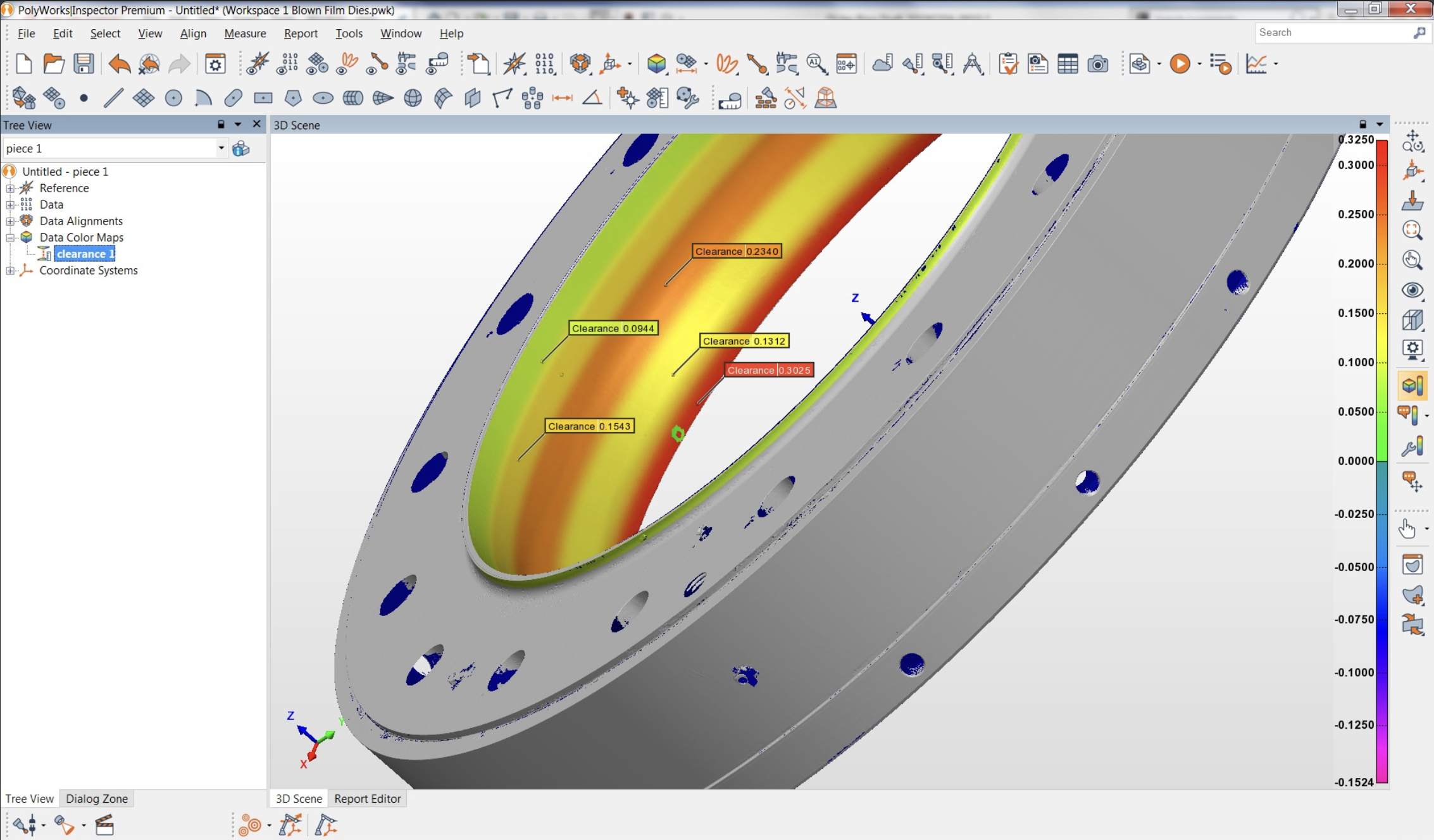

Reverse Engineering, as it relates to 3D Measurement Services, is a process that involves capturing the physical dimensions and characteristics of an existing object or component to create a digital 3D model. This technique is widely used in various industries, including manufacturing, engineering, product design, and maintenance. At Rotatek, Reverse Engineering can be accomplished with the use of our Laser Trackers, Arms and Scanners.

how Can we Help you?

Our expert team is ready to help you with your next project. Explore the industries we serve or contact us to learn more.

The primary goal of Reverse Engineering is to recreate a physical object or component in digital form. There are several reasons why this process is undertaken including Product Design Improvement and Manufacturing, Legacy Part Reproduction and Inoperability and Integration.

Reverse Engineering allows engineers and designers to study and analyze an existing product to understand its structure and functionality better. This knowledge can lead to design improvements or modifications to enhance performance, reduce costs, or incorporate new features.

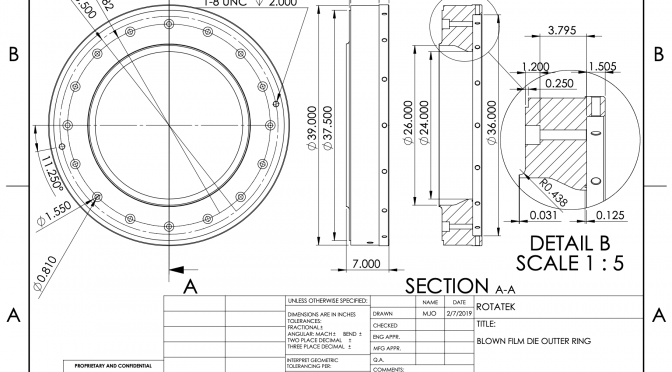

The final step involves converting the reconstructed 3D model into a Computer-Aided Design (CAD) format. CAD models allow engineers and designers to work with the digital model, modify it, and use it for various purposes, such as simulations, 3D printing, or integration into other designs.