Vibration analysis is a technique Rotatek uses to study and assess the behavior of mechanical systems, structures, or components in response to vibrations. The objective of vibration analysis is to understand the causes of vibrations, their characteristics, and their impact on the performance and reliability of the system. It is widely used in various industries, including manufacturing, aerospace, automotive, and engineering, to diagnose problems, monitor equipment health, and optimize designs.

Vibration analysis is a powerful tool for diagnosing and understanding the behavior of mechanical systems. It aids in improving product quality, increasing equipment reliability, and reducing maintenance costs by identifying and addressing vibration-related problems at an early stage.

Rotatek provides on-site vibration analysis services and condition monitoring services for industrial rotating equipment. Our ISO certified vibration analysts can diagnose, identify, predict and prevent faults in rotating machinery.

Vibration Analysis is used to evaluate and detect faults in rotating equipment such as electric motors, pumps, fans, blowers, turbines, compressors, gearboxes, etc. Vibration measurements acquired on rotating machinery can be analyzed to identify both mechanical and electric faults such as rotor unbalance, misalignment, looseness, bearing faults, and more.

From installation to overhaul and maintenance, Rotatek’s vibration analysis services can validate machine performance ensuring safe, efficient and reliable operation.

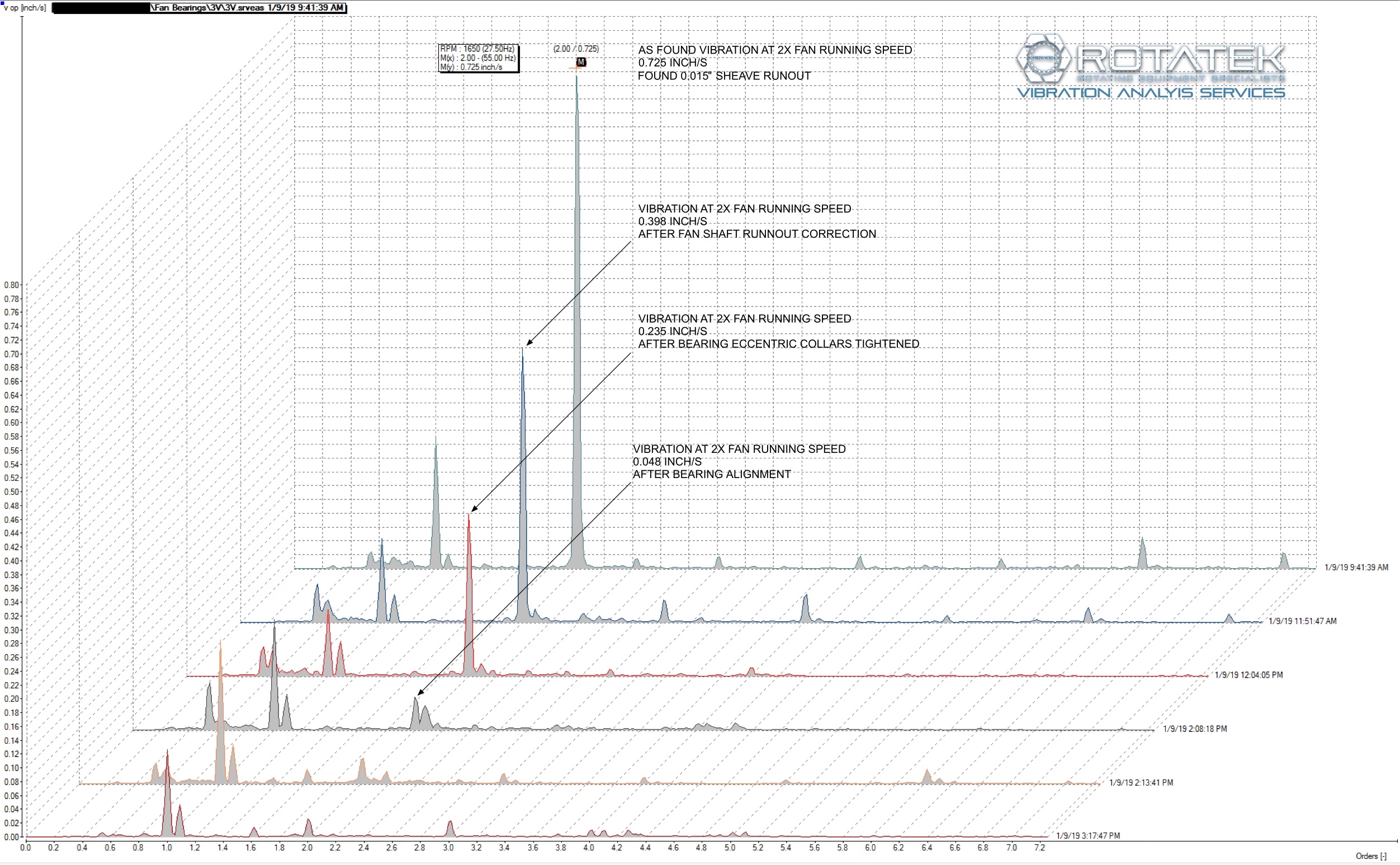

A detailed graphical measurement report is supplied with all precision measurement services.

how Can we Help you?

Our expert team is ready to help you with your next project. Explore the industries we serve or contact us to learn more.