3D Metrology Services You Can Trust

At ROTATEK, precision isn’t just part of our process—it’s our promise. As a trusted leader in on-site precision measurement services, we deliver cutting-edge 3D metrology services that help manufacturers, engineers, and quality teams solve their toughest measurement challenges with confidence.

Whether you’re performing tight-tolerance alignment inspections in the field, reverse engineering legacy parts, or validating first articles, we bring the technology, certification, and expertise to get the job done right.

Furthermore, backed by AS9100D and ISO 9001:2015 certifications, NIST-traceable equipment, and decades of real-world experience, ROTATEK ensures every measurement is performed with accuracy, precision, rigor, and purpose. In short, we don’t just measure—we deliver insight.

Let us show you how metrology done right can transform your project’s speed, performance, and quality outcomes.

how Can we Help you?

Our expert team is ready to help you with your next project. Explore the industries we serve or contact us to learn more.

3d METROLOGY SERvICES & SOLUTIONS

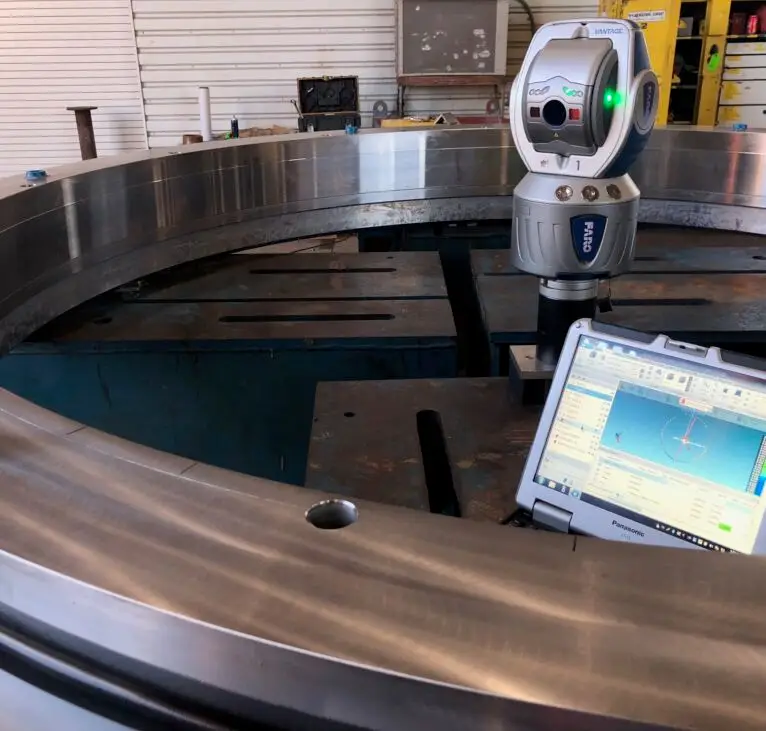

At ROTATEK, precision drives our 3D Metrology Services. Using advanced Leica and Faro systems, we deliver accurate inspections for parts and assemblies, ensuring compliance with industry standards. Whether you need large-scale measurements, GD&T analysis, or complex alignments, our experienced team provides reliable, tailored solutions.

Moreover, our advanced laser trackers, equipped with both contact and non-contact capabilities, allow for unparalleled flexibility and accuracy in capturing complex geometries. From probing tight internal features to scanning large out of reach surfaces, we tailor our approach to match the specific needs of your component or system—without compromising precision.

WHAT IS 3D METROLOGY?

3D metrology involves the precise measurement and analysis of an object’s geometry in three dimensions. Utilizing state-of-the-art equipment, we capture detailed surface data to assess form, fit, and function, enabling comprehensive dimensional inspection and analysis, quality control and reverse engineering.

Our Capabilities

- 3D Alignment: Achieve precise alignment of machinery, components, and structures to optimize performance and minimize wear.

3D Scanning: Capture intricate details of components, regardless of size or complexity.

Dimensional Inspection: Verify that parts conform to design specifications and tolerances.

Reverse Engineering: Generate accurate CAD models from existing parts for redesign or reproduction.

Surface Analysis: Assess surface roughness and texture to ensure optimal performance.

Geometric Dimensioning & Tolerancing (GD&T): Comprehensive analysis to ensure components meet precise engineering standards.

Our Portable CMM (PCMM) Systems

At ROTATEK, we utilize a diverse fleet of industry-leading Portable Coordinate Measuring Machines (PCMMs) to deliver fast, accurate, and highly repeatable measurement and alignment services—anywhere in the world.

Our systems support precision measurement of complex geometries, large assemblies, and in-place components, even in harsh or dynamic environments. From laser trackers to scanning arms, our PCMM lineup ensures optimal results across aerospace, defense, marine, and industrial applications.

Leica AT960-XR with T-Probe

High-performance laser tracker with 6DoF probing and real-time tracking for large-scale inspections.Leica LAS & LAS-XL Scanners

High-speed laser scanning for large-volume, high-accuracy surface and geometry capture.Leica ATS600

Direct-to-surface scanning trackers—ideal for inaccessible or delicate surfaces, enabling contactless inspection over large areas.- Leica ATS500

Long range laser tracker up to 180m radial distance.

- Faro Vantage & Vantage S

Lightweight, portable laser trackers with exceptional accuracy and portability for demanding field environments.

Faro Quantum S ScanArm

Versatile, 7-axis articulated arm with high-resolution laser scanning—perfect for tight-tolerance inspection of parts, assemblies, and tooling.

Whether it’s high-speed production metrology, complex fixture verification, or mobile large-volume scanning, ROTATEK’s PCMM systems are ready to meet your most challenging measurement needs—on-site, in-field, or on the floor.

Certified Quality Assurance

As an AS9100D and ISO 9001:2015 certified company, ROTATEK is committed to delivering services that meet and exceed industry quality standards. Our certifications reflect our dedication to continuous improvement and customer satisfaction.

Industries We Serve

Our 3D metrology services support a diverse range of industries, including:

Aerospace: Ensuring components meet strict regulatory and performance standards.

Defense: Providing precise measurements for mission-critical equipment.

Power Generation: Maintaining the integrity of turbines and related components.

Marine: Supporting the alignment and inspection of shipbuilding elements.

Manufacturing: Enhancing quality control and product development processes.

Why Choose ROTATEK?

Expert Technicians: Our team comprises experienced professionals trained to handle complex measurement tasks.

Advanced Technology: We invest in the latest metrology equipment to provide accurate and efficient services.

Nationwide Service: Offering 24/7 availability to meet your project timelines and reduce downtime.

Customized Solutions: Tailoring our services to meet the unique needs of each client and project.

Contact Us

Ready to ensure the precision and quality of your components? Contact ROTATEK today to learn more about our 3D metrology services and how we can support your project’s success.