At ROTATEK, we deliver precision roll alignment services for web-handling systems across industries such as paper, printing, converting, steel, and packaging. Utilizing state-of-the-art laser tracker technology, we ensure that rolls are parallel, level, and square to each other and perpendicular to the web path, enhancing product quality and reducing machine wear.

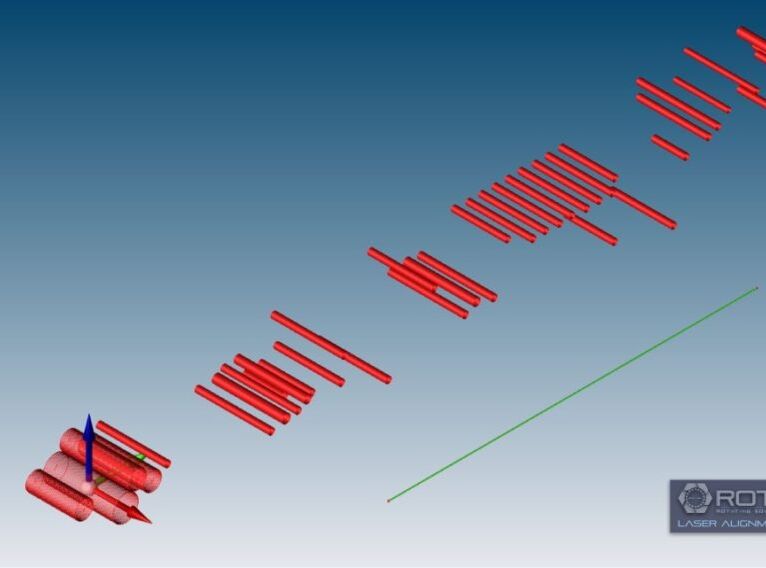

Web Handling Roll Alignment refers to the precise positioning of a web of material as it moves through web handling system, such as a printing press, laminating machine or converting line. This is achieved by aligning the rolls of the machine so they are parallel, level and square to each other and perpendicular to the web path.

Our field service service engineers utilize state-of-the-art laser equipment enabling us to to perform these services faster with higher accuracy and greater precision.

From installation to overhaul and maintenance, our machine train alignment service solutions can out-perform traditional methods saving valuable outage time and resources.

A detailed graphical measurement report is supplied with all precision measurement services.

Our commitment to excellence paired with our state-of-the-art measurement capabilities makes Rotatek your trusted precision service partner.

how Can we Help you?

Our expert team is ready to help you with your next project. Explore the industries we serve or contact us to learn more.

Proper roll alignment is critical for maintaining consistent quality and avoiding production problems.

Unlike traditional alignment methods using a straight edges, or dial indictors, Rotatek field engineers utilize state-of-the-art 3D laser trackers for unparalleled accuracy, precision and measurement acquisition time.

Web handling roll alignment is a complex process that requires careful planning, attention to detail and highly skilled operators in order to achieve accurate, reliable results in a timely and efficient manner.

3D Measurements

Laser trackers operate by measuring two angles and a distance. The tracker sends a laser beam to a retroreflective target held against the object being measured. As light is reflected off the target, it bounced back and re-enters the tracker at the same position it left and is measured by a distance meter, measuring the distance between the tracker and target.

Why Roll Alignment Matters

Misaligned rolls can lead to:

Material Waste: Inconsistent tension and tracking issues.

Product Defects: Uneven coatings, wrinkles, and web breaks.

Increased Wear: Excessive stress on bearings and other components.

Proper alignment ensures:

Consistent Product Quality: Uniform tension and accurate tracking.

Reduced Downtime: Minimization of unexpected maintenance.

Extended Equipment Life: Less strain on machine components.

Our Alignment Process

Assessment: Evaluate the current alignment state of your roll system.

Measurement: Employ laser trackers to capture precise 3D positions of each roll.

Analysis: Determine deviations from optimal alignment.

Adjustment: Realign rolls based on accurate data.

Verification: Confirm alignment through re-measurement.

Advanced Technology

Our laser trackers measure two angles and a distance to determine the exact 3D position of each roll. This method provides:

High Precision: Accurate to within micrometers.

Speed: Rapid data acquisition reduces downtime.

Comprehensive Reports: Detailed graphical reports for QA and compliance.

Industries Served

Paper and Pulp

Printing and Converting

Steel and Metal Processing

Packaging

Textiles

Why Choose ROTATEK?

Expertise: Experienced technicians with industry-specific knowledge.

Technology: Utilization of the latest laser tracking equipment.

Quality Assurance: Detailed documentation for every project.

Customer Focus: Tailored solutions to meet your specific needs.

Contact us today to schedule your roll alignment service and ensure optimal performance of your web-handling systems.