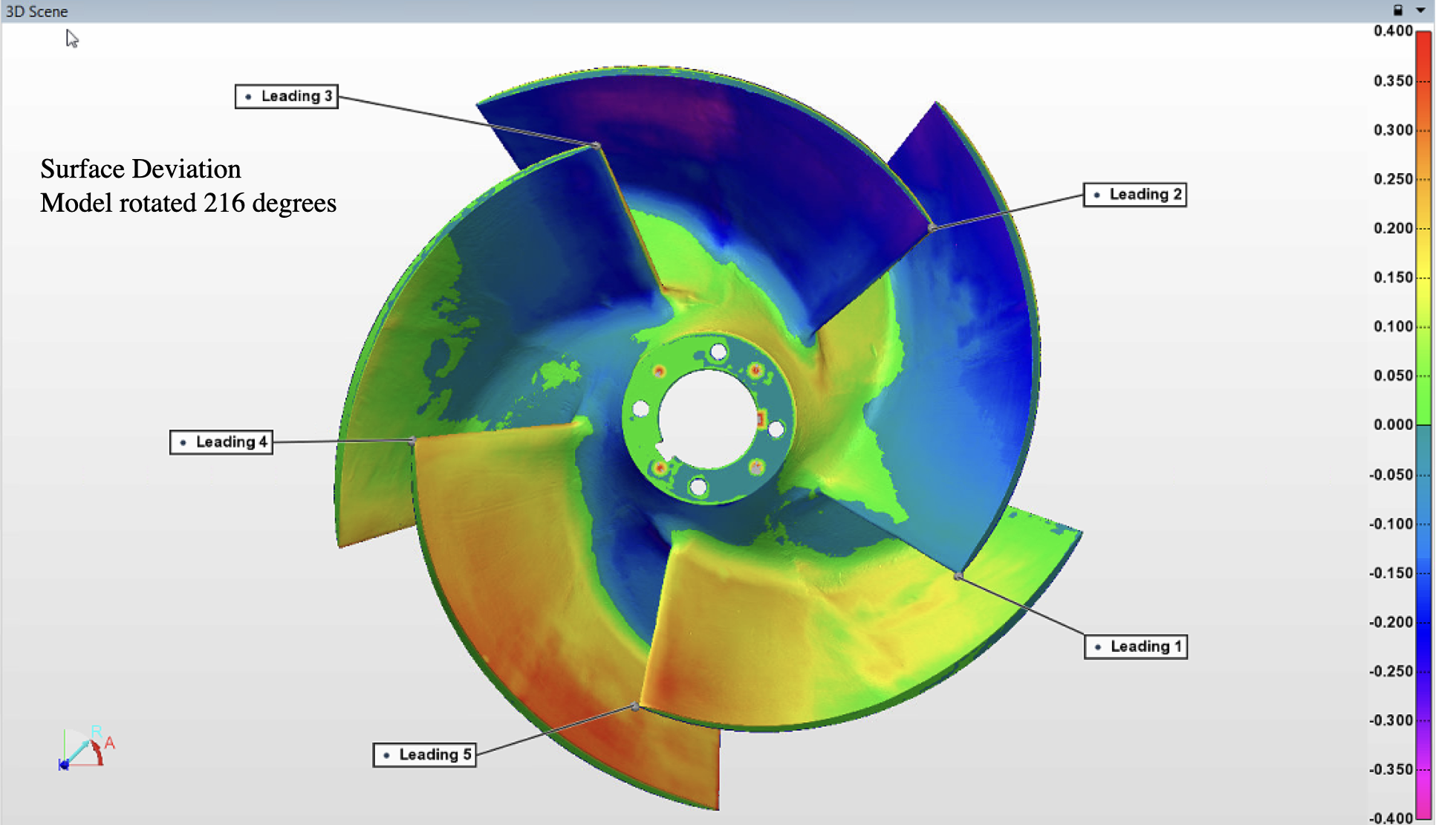

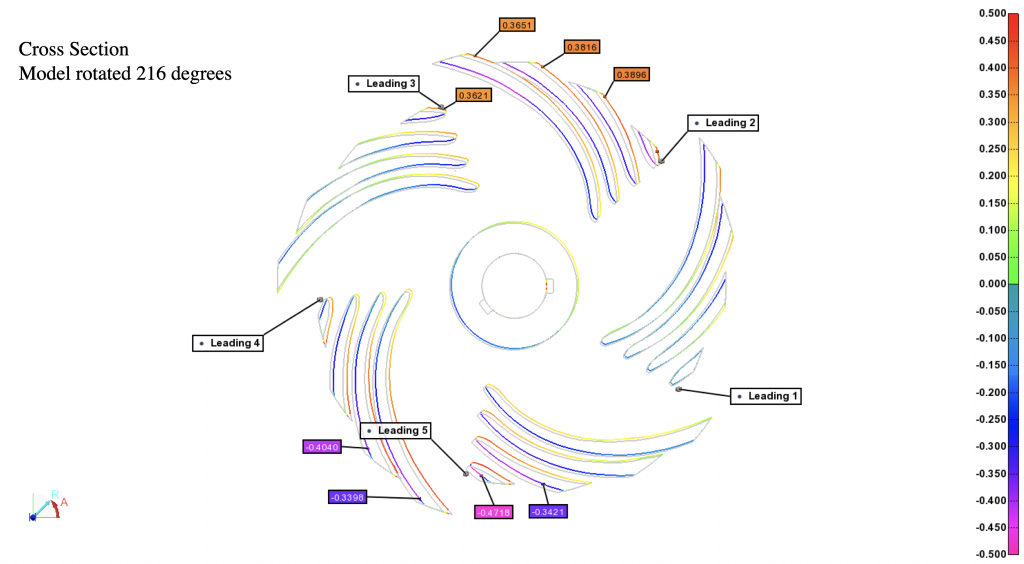

Dimensional inspection and analysis are processes that involve measuring and evaluating physical components to ensure they meet specified dimensional and geometric requirements. These processes are crucial in manufacturing and quality control to verify that parts are produced within acceptable tolerances and adhere to design specifications.

Dimensional inspection and analysis play a critical role in ensuring the quality and consistency of manufactured components. By utilizing advanced measurement tools and techniques, Rotatek can help manufacturers identify and address deviations early in the production process, leading to improved product quality and adherence to design specifications.

how Can we Help you?

Our expert team is ready to help you with your next project. Explore the industries we serve or contact us to learn more.

Laser trackers operate by measuring two angles and a distance. The tracker sends a laser beam to a retroreflective target held against the object being measured. As light is reflected off the target, it bounced back and re-enters the tracker at the same position it left and is measured by a distance meter, measuring the distance between the tracker and target.

The target returns the reflected laser beam parallel but offset back to the tracker where it hits the position detector, which calculates the offset between the outgoing and incoming beam. Servo motors continuously (thousands of times per second) steer the tracker’s head to minimize the offset between the two beams, resulting in high-speed, dynamic measurements.