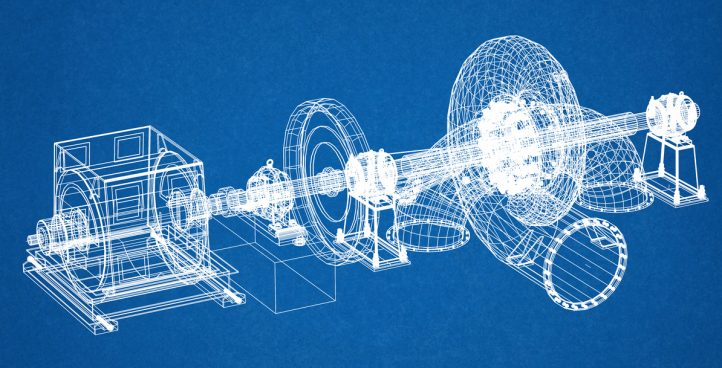

Machine train alignment is a crucial part of industrial maintenance that involves aligning multiple machines to ensure optimal performance, reliability and efficiency. A machine train is a machine that has at least three separate machines and two couplings.

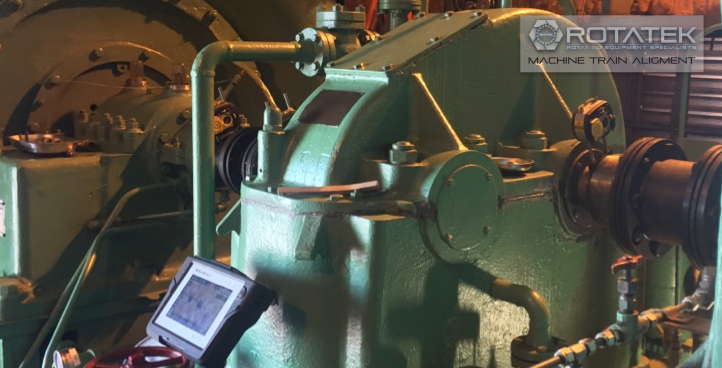

ROTATEK utilizes state-of-the art laser alignment systems and methods to measure multiple machine couplings simultaneously. Once measured, the machine train’s alignment results are analyzed and an alignment solution that minimizes machine moves is implemented. Alignment moves are first proven with the alignment computer’s simulator to confirm an in-tolerance move can be achieved. Simultaneous multi-coupling live move allows for the horizontal and vertical machine moves to be monitored live.

ROTATEK’s ability to simultaneously measure, simulate moves and monitor moves live saves time, money and gets you back online faster than traditional methods.

From installation to overhaul and maintenance, our machine train alignment service solutions can out-perform traditional methods saving valuable outage time and resources.

A detailed graphical measurement report is supplied with all precision measurement services.

Our commitment to excellence paired with our state-of-the-art measurement capabilities makes ROTATEK your trusted precision service partner.

how Can we Help you?

Our expert team is ready to help you with your next project. Explore the industries we serve or contact us to learn more.

Machine Train Alignment is the process of aligning the rotational centerlines of three or more shafts in a machine.

Unlike traditional alignment methods using a straight edges, or dial indictors, ROTATEK field engineers utilize state-of-the-art laser equipment for unparalleled accuracy, precision and measurement acquisition time.

Industrial machine train alignment is a complex process that requires careful planning, attention to detail and highly skilled operators in order to achieve accurate, reliable results in a timely and efficient manner.