At ROTATEK, we deliver industry-leading steam turbine alignment and precision measurement services utilizing the most advanced 3D metrology and laser alignment technologies available. Our skilled field engineers specialize in internal bore alignment, rotor and casing alignment, bearing pedestal alignment, and full turbine train alignment—whether during scheduled outages, overhauls, or emergency service. Using state-of-the-art laser tracker systems, we complete alignments more quickly and with superior accuracy, ensuring your steam turbine meets OEM tolerances while minimizing vibration, enhancing efficiency, and extending equipment life.

From initial installation and commissioning to routine maintenance and major overhauls, our steam turbine laser alignment services surpass traditional methods—reducing outage durations, lowering operational costs, and optimizing your workforce and resources.

Whether you operate in power generation, industrial manufacturing, petrochemical, or cogeneration facilities, our expert technicians and advanced diagnostic tools are prepared to handle even the most complex alignment challenges with precision and professionalism.

Every service includes a comprehensive graphical measurement report detailing all alignment data and tolerance verification for full OEM compliance.

ROTATEK’s unwavering commitment to excellence, combined with cutting-edge measurement capabilities, makes us your trusted partner for precision steam turbine alignment services.

how Can we Help you?

Our expert team is ready to help you with your next project. Explore the industries we serve or contact us to learn more.

STEAM TURBINE Alignment and Measurement Solutions

Steam Turbine Alignment is is critical to ensure that the rotor and stator components are concentric and that the axial and radial clearances between the rotating and stationary components are within acceptable limits.

Unlike traditional alignment methods using a straight edges, or dial indictors, ROTATEK field engineers utilize state-of-the-art laser equipment for unparalleled accuracy, precision and measurement acquisition time.

Industrial turbine alignment is a complex process that requires careful planning, attention to detail and highly skilled operators in order to achieve accurate, reliable results in a timely and efficient manner.

BORE ALIGNMENT

GENERATOR ALIGNMENT

MACHINE TRAIN ALIGNMENT

DYNAMIC MOVEMENT STUDY

FOUNDATION ALIGNMENT

GEARBOX ALIGNMENT

What We Align in STEAM Turbines

Internal Steam Path Components

Precision alignment of diaphragms, inner casings, bearing pedestals, seal housings, and stationary flow-path elements to maintain critical clearances, concentricity, and axial alignment throughout the turbine section.

Rotor & Shaft Assemblies

Laser alignment of high-pressure (HP), intermediate-pressure (IP), and low-pressure (LP) rotor shafts to ensure proper centerline positioning, balanced rotation, and smooth coupling engagement across multiple turbine sections.

Gearbox & Generator Couplings

Accurate alignment of turbine-to-gearbox and gearbox-to-generator couplings to reduce torsional stress, improve power transmission efficiency, and minimize vibration across the machine train.

Foundations & Baseplates

Verification of baseplate flatness, level, and anchor bolt locations to ensure long-term structural support and alignment integrity for bearing housings, casings, and auxiliary equipment.

Full Turbine Train Systems

End-to-end alignment of the complete steam turbine train—including rotors, gearboxes, and generators—to deliver optimal drivetrain performance, thermal growth accommodation, and long-term operational reliability.

STEAM Turbine Alignment Services

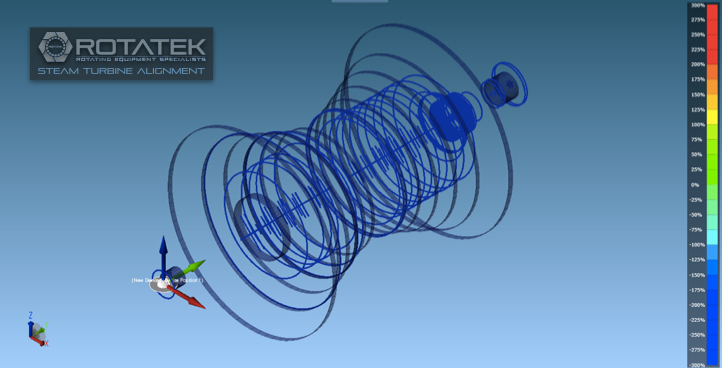

3D Internal Bore & Casing Alignment

Using state-of-the-art laser trackers, we measure and align bore centers, casing halves, diaphragms, bearing pedestals, seal housings, and other internal stationary components to OEM-specified tolerances. This alignment maintains critical concentricity and prevents mechanical interference or flow-path disruption.

-

Ensures precise axial and radial positioning of diaphragms, seals, and flow-path hardware

-

Maintains optimal rotor-to-stator clearances for peak aerodynamic efficiency

-

Prevents premature wear, rubbing, and steam leakage caused by misalignment

-

Supports reliable rotor installation and efficient long-term turbine operation

Rotor & Coupling Alignment

We perform precise laser shaft alignment across the steam turbine rotor sections (HP, IP, LP) and coupling interfaces with gearboxes and generators. Both cold and hot alignment methods are applied to account for thermal growth and operating conditions.

-

Reduces torsional stresses and minimizes coupling misalignment to prevent premature failure

-

Enhances bearing and seal life by limiting misalignment-induced loads

-

Improves overall system efficiency through balanced, smooth rotation

-

Utilizes thermal growth modeling to maintain alignment during startup and full-load operation

Bearing Pedestal Alignment

Accurate positioning of journal and thrust bearing housings is critical to ensure even load distribution and stable rotor dynamics. Our laser tracking technology guarantees bearing supports are precisely aligned within OEM geometric tolerances.

-

Maintains concentricity between rotor shafts and bearing supports for smooth rotation

-

Prevents edge loading, oil film instability, and bearing fatigue

-

Supports vibration control and optimal rotor dynamics

-

Verifies alignment across vertical, horizontal, and axial planes

Dynamic Movement Study

Steam turbines experience shaft and casing movement due to thermal expansion, load changes, and structural effects during operation. Our dynamic movement studies measure and model these positional shifts to:

-

Quantify growth, sag, and lateral displacement of major components

-

Predict thermal offsets and dynamic misalignment conditions

-

Provide correction strategies before hot startup and full-load operation

-

Ensure shaft and coupling alignment accounts for real-world operating conditions

Foundation Alignment

A level and stable foundation is essential for maintaining long-term turbine alignment. We verify flatness, levelness, and anchor bolt positioning of skid bases and foundations using laser trackers and precision leveling tools.

-

Perform flatness and level checks on baseplates and foundation skids

-

Verify anchor bolt and pedestal locations to OEM specifications

-

Conduct leveling and correction analysis to prevent distortion

-

Monitor foundation movement under thermal and operational loads

This foundation integrity supports reliable bearing and casing alignment and prevents long-term structural stresses.

Full Steam Turbine Train Alignment

Our comprehensive machine train alignment service covers the entire steam turbine train—including HP/IP/LP turbines, gearboxes, generators, and driven equipment—to ensure seamless drivetrain operation.

-

Minimizes vibration and mechanical stresses throughout the drivetrain

-

Optimizes torque transmission and reduces wear on couplings

-

Supports smooth startups and enhances operational stability

-

Utilizes laser tracker and optical tooling for multi-axis, high-precision alignment

Aligning the full turbine train as a system maximizes reliability and extends asset life.

Reporting & OEM Compliance

All alignment activities are thoroughly documented with detailed as-found and as-left reports. We provide 3D measurement datasets, tolerance analyses, and correction records that comply with or exceed OEM and industry standards.

Why Gas Turbine Alignment Matters

Steam turbines operate under intense thermal, mechanical, and rotational stresses in power generation and industrial processes. Precise alignment of internal and external components is critical to achieving reliable performance, efficiency, and operational safety. Even minute misalignments can cascade into serious issues, reducing output and increasing costly downtime.

Key Reasons Proper Alignment Is Essential:

Minimizes Rotor Vibration & Fatigue

Misalignment creates unbalanced forces across the rotor train, increasing vibration and accelerating fatigue in shafts, couplings, and bearings. This can lead to premature equipment failure or catastrophic damage.

Preserves Bearing and Seal Health

Journal and thrust bearings require exact axial and radial alignment to maintain optimal oil film thickness and lubrication. Misalignment disrupts hydrodynamic bearing performance, causing overheating, accelerated wear, and early failures. Similarly, seals depend on precise positioning to prevent steam leaks.

Maintains Aerodynamic Efficiency

Internal stationary components such as diaphragms, casings, and seals must be concentric with the rotor shaft. Misalignment increases clearances or causes rubbing, which reduces steam flow efficiency and lowers turbine output.

Reduces Forced Outages & Maintenance Costs

Undetected or uncorrected misalignment leads to increased vibration alarms, bearing and seal failures, and emergency shutdowns. Precision alignment during installation, outage, or overhaul prevents these issues, reducing unplanned downtime.

Improves Thermal Growth Management & Dynamic Response

Steam turbines undergo significant thermal expansion during startup and operation. Alignment procedures that incorporate thermal growth and dynamic movement studies ensure rotor centerline and coupling alignment are maintained under full-load conditions.

Ensures OEM Compliance & Maximizes Asset Life

Turbine manufacturers specify stringent alignment tolerances to guarantee design life and performance. Professional alignment services ensure these tolerances are consistently met, documented, and support long-term equipment reliability.

Integrated Metrology Solutions

We also offer complementary services that support your alignment needs:

Each of these services is designed to ensure your equipment, assemblies, and tooling not only meet design intent but perform to exacting standards.

Why Choose ROTATEK?

At ROTATEK, precision is more than a goal—it’s our standard. Backed by AS9100D and ISO 9001:2015 certifications, we uphold globally recognized benchmarks for quality in every service we deliver. With decades of hands-on experience in laser alignment, 3D metrology, and precision measurement, our team brings unmatched accuracy and reliability to every project.

We serve high-stakes industries including aerospace, defense, power generation, marine, and more—adapting to complex environments with speed, skill, and confidence. Our field engineers are available 24/7, mobilize quickly across the U.S., and operate under a robust quality management system designed for mission-critical performance.

We use the latest equipment and industry-trusted software—from FARO, LEICA, and PRUFTECHNIK—to ensure your components meet the tightest tolerances, every time.

Certified Quality

-

AS9100D and ISO 9001:2015

Always Ready

-

24/7 Availability & Nationwide Rapid Response

Advanced Tools

-

Industry-Leading Equipment: FARO, LEICA, PRUFTECHNIK

Proven Expertise

- Trusted Across Aerospace, Defense, Power Gen & Marine

Ready to Align with Excellence?

Contact us today to schedule your steam turbine alignment service or to discuss a custom solution tailored to your operational and equipment needs.